Baotou company makes breakthrough in steel manufacturing

Bao Gang United Steel has announced the delivery of its first mass production of 122 metric tons of high-strength container steel for large low-temperature spherical tanks, marking the company's breakthrough in steel for energy equipment.

The company's large low-temperature spherical tanks. [Photo/Baotou news network]

Large low-temperature spherical tanks, with their uniform stress distribution, high space utilization, and relatively small footprint, are mainly used in the energy, chemical, and metallurgical fields for storing low-temperature materials.

The steel used to construct spherical tanks is medium-thick plates that have a tensile strength of 610MPa. These plates are required to have high strength, low temperature toughness at minus 50 C, crack resistance, bend performance, strain aging performance, simulated post-weld heat treatment performance (PWHT), and excellent welding performance, while ensuring safe and stable operation under harsh working conditions from minus 50 C to over 100 C.

In early June, Bao Gang United Steel decided to undertake this batch of orders after strict technical evaluations. Faced with challenges such as short delivery time and synchronous promotion of R&D and mass production, the technical team analyzed the technical requirements of the steel plates, developed a complete set of new quality plans and production schemes, and adopted the technical route of "small batch trial production-process optimization-mass production".

Through repeated process optimizations, the team overcame the matching difficulties of key indicators such as steel plate chemical composition, heat treatment processes, tensile performances, and -50 ℃ low-temperature impact energy.

The project team implemented close tracking throughout the entire process to ensure that each steel plate was delivered on time with the highest standard, winning high recognition from customers.

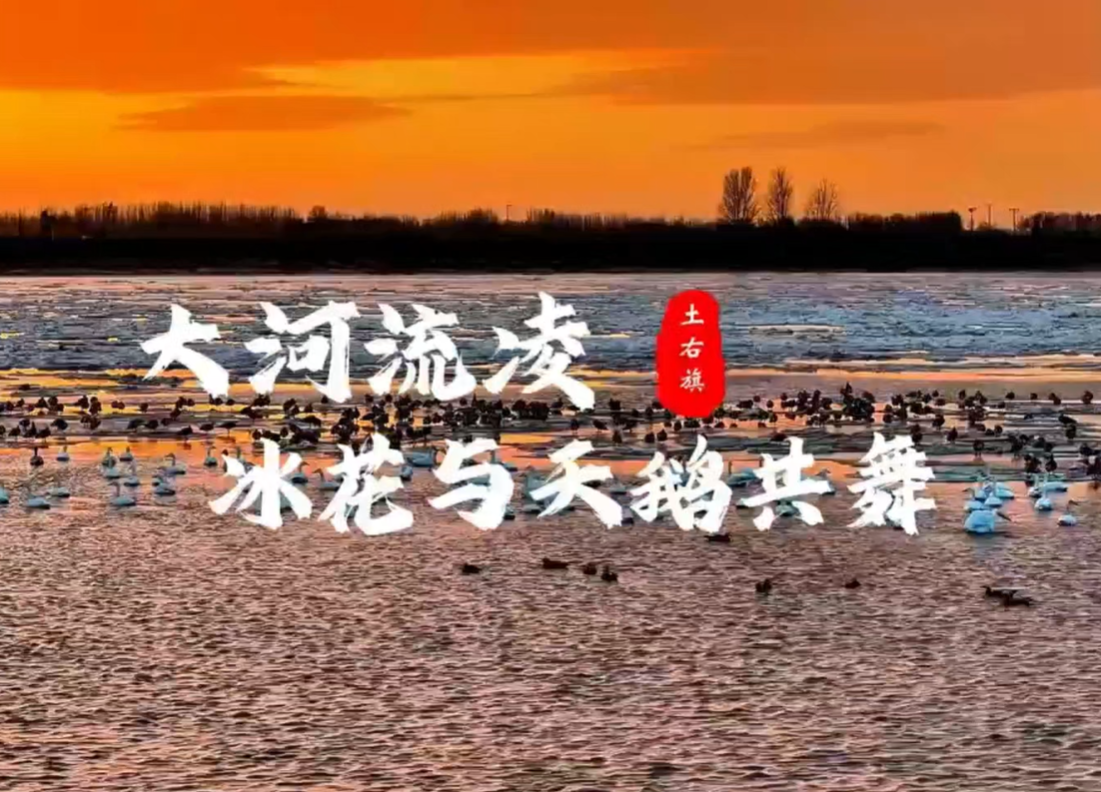

Ice floats & swans in Baotou

Ice floats & swans in Baotou