Baotou achieves breakthrough in hydrogen recycling

The "Rare Earth Solid State Hydrogen Storage — Hydrogen Recovery System" developed by the Baotou Research Institute of Rare Earths has been put into operation on the production line.

For the first time in China's large-scale production of rare earth functional materials, this technology has enabled efficient hydrogen recovery and recycling, filling a key technological gap in the field.

Neodymium-iron-boron is an important rare earth functional material, with an annual production of over 300,000 metric tons in China. Hydrogen fragmentation is a key process in the preparation of high-performance neodymium-iron-boron powder.

Li Jin, a representative of the institute, said that the traditional production process generates 5 to 6 kilograms of hydrogen gas for every ton of neodymium-iron-boron flakes produced, resulting in significant resource waste. The current rare earth solid-state hydrogen storage device is capable of increasing the recovery rate of hydrogen gas to over 95 percent.

The system not only provides replicable carbon reduction and efficiency improvement solutions for hydrogen-consuming industries, but also opens up new paths for the application of high-abundance rare earths like lanthanum and cerium. The team will continue to promote and optimize the technology, assisting in the high-quality, green, and sustainable development of the hydrogen energy and rare earth industries.

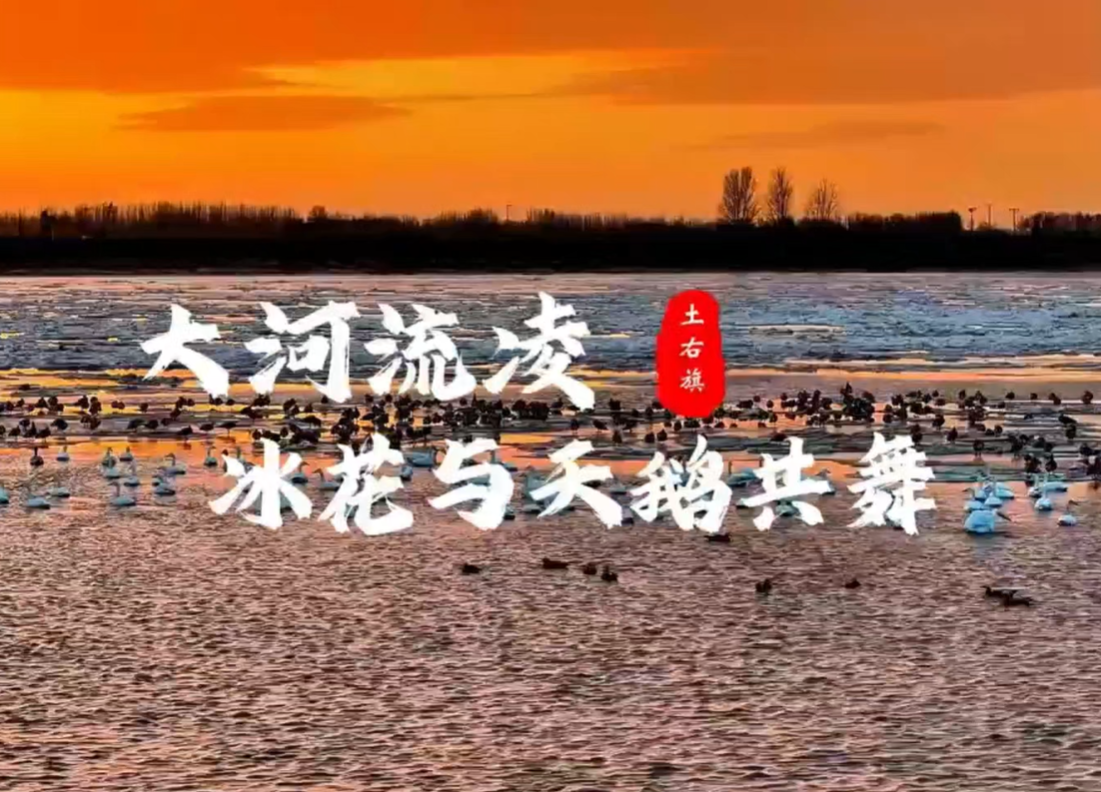

Ice floats & swans in Baotou

Ice floats & swans in Baotou